Defining the cutting-edge of advanced manufacturing

With over 50 product categories and nearly 100,000 configurations for research and development, LSSC can produce a wide range of products, including desktops, workstations, servers, while serving as a R&D hub for cutting-edge products, such as smart modules and home appliances. These offerings are sold in over 180 countries and regions, making the factory a major global player in the technology sector.

Intelligent manufacturing, which uses AI and interconnected sensors, enables LSSC to meet complex order requirements. With the help of Smart Process System (ESOP) and digital 3D operating instructions, LSSC can adapt precisely and seamlessly—meaning almost instantaneous switching from one product or process to another. Customized orders that typically take 10-20 days in traditional manufacturing can now be delivered in just one or two days.

In just one example, computer vision technology automates the inspection of LCD panels with artificial intelligence. Compared with manual, traditional detection, the LSSC is already seeing cost reduced by 50 percent, both efficiency and accuracy improved by 30 percent, and the continuous detection can be carried out 24/7 without breaks.

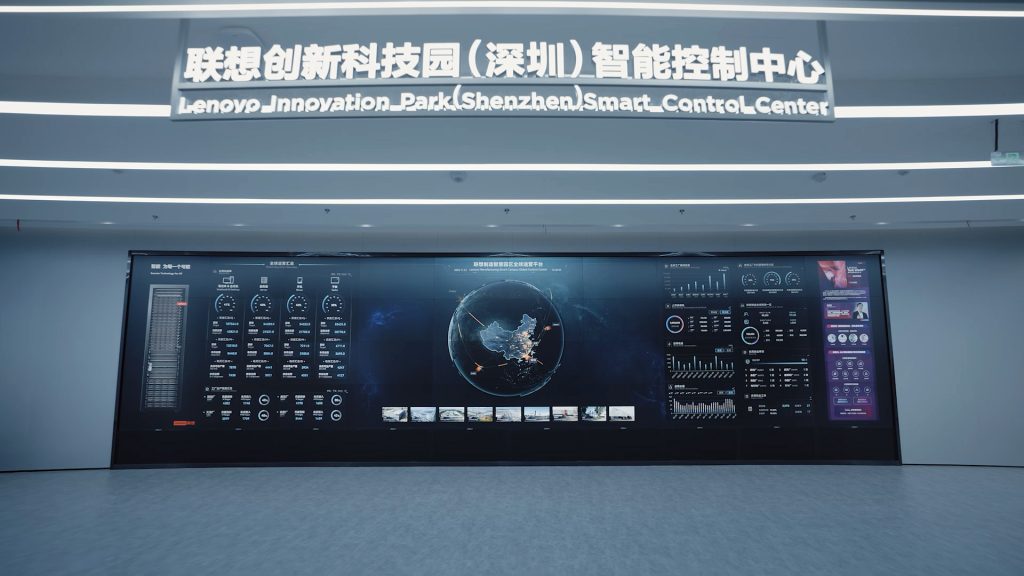

Currently, LSSC has nine highly automated benchmark production lines and 12 digital solutions. Its control platform is the most advanced, well-equipped, and comprehensive in China’s manufacturing industry, being able to operate across multiple facilities worldwide.

“Based on Lenovo’s strong R&D capability, the ‘mother factory’ is progressively integrating and rolling out our innovative solutions across devices, edge and cloud computing, networks, and artificial intelligence businesses, ” said LSSC general manager Meng Fanyi.

In the years to come, LSSC will expand its reach even further, providing customized products for large enterprises around the world, as well as supporting numerous small- and medium-sized enterprises to incubate new products and explore the possibilities of advanced manufacturing.